Integrated prefabricated pumping station

Post Buying Request

Durable Pit Shaft Design

The first pit shaft one-time formed with computer-controlled integral winding technology in the industry to eliminate leakages and cracks caused by manual secondary connection

100% alkali free high quality resin with zero additives

GRP content up to 75%

Bottom wall thickness increased by up to 20% to resist higher pressure

Zero leakage

Service life of pit shaft up to 30 years

GRP Pit Shaft vs. Concrete Water Reservoir

|

GRP Pit Shaft |

Concrete Water Reservoir |

||

|

30000T/D for example |

30000T/D for example |

||

|

Lead time |

15 days |

Lead time |

Min. 60 days |

|

Footprint |

30-40m² |

Footprint |

150-200m² |

|

Leakage/cracks |

No |

Leakage/cracks |

Commonly seen |

|

Odor |

No |

Odor |

Strong |

|

Compressive strength |

371MPa |

Compressive strength |

20MPa |

|

Environmental friendliness |

No pollution to groundwater |

Environmental friendliness |

Risk of pollution caused by leakage |

|

Manufacturing cost |

Unattended process with computer-controlled integral winding technology |

Manufacturing cost |

Expensive labor cost |

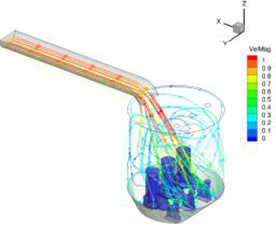

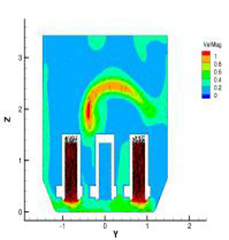

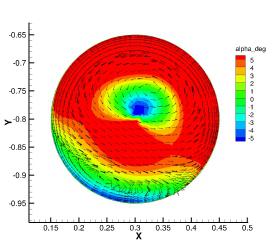

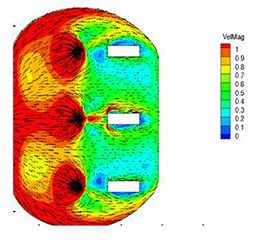

Excellent Pump Pit Design

CFD designed pump pit with less sediments in the bottom and less odor

National patent technologies applied

Test results show that sedimentation in the bottom can be solved by CFD pump pit plus flushing valves

Standardized Factory Prefabrication

Lean production for higher quality; attention to details for perfect experience.

All parts go through strict tests before assembly

High Matching degree of parts

Scientific and rigorous process

Whole process inspections and tests before delivery

Original data archived for future reference

Unattended Process

Intelligent control ensures unattended operation

CPRS remote monitoring puts everything under control

Outdoor design with control system integrated into the top of pump station or installed nearby

Model Selection Guide

Model Selection of Pump Stations

Before selecting a suitable model, we need to know:

1. Parameters and elevations

Designed flow rate and lift

Number of pumps, including working pumps and standby pumps. Floor elevation, inlet/outlet pipe elevations. Inlet/outlet pipe diameter.

2. Application

Intended application, including civil works, industries, constructions or other indoor/outdoor, aboveground/underground, media type, temperature, etc.

3. Structural type

Modular wet dip pump station (standard), modular integrated pump station, wet dip pump station with a service room or customized pump station.

4.Material of internal pipes, 304 stainless steel (standard) or 316.

5.Level sensor and pressure sensor (standard), floating ball switch, or ultrasonic level sensor (optional).

6. Bucket type grille (standard), shredder grille, simple deodorizing device, lifting device.

7.Control system, automatic level control, manual control or GPRS remote control.

Highly Durable GRP Shaft Body

Post Buying Request

Items with "*" are required to fill in.